Safety, health issues in rubber sector

N Yogaratnam, Phd (London), Tree crops Agro

Consultants

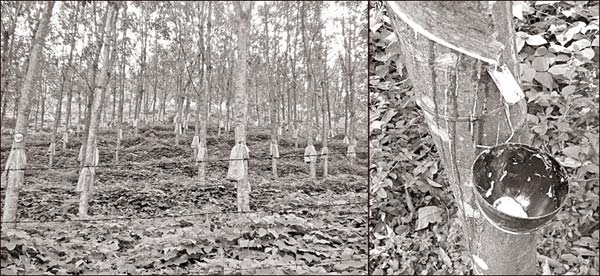

Safety and health in the rubber

growing, processing and products manufacturing sector had been a

neglected subject, though this sector is still a major foreign exchange

contributor to the national economy in Sri Lanka, with significant

contribution of Rs 72.3 billion in 2008.

Many mechanical and chemical hazards exist in the plantations, where

a large number of unskilled and semi-skilled workers are employed.

Due to management and worker ignorance, negligent use of fertilizers

and pest and weed controlling and rubber products manufacturing

chemicals and bad work practices in some estate factories, serious

hazards have been created and many accidents have occurred.

|

It is necessary to integrate a clear occupational safety and

health policy in national development plans. |

About 15 percent of the total poisonings and deaths in Sri Lanka are

caused due to occupational accidents due to the intake of harmful

substances.

The impact of these harmful substances that enter the environment has

been quantified ( ILO, 2001).

Yet, like in any other employment sector, workers in the rubber

industry run an equal if not higher risk of being injured as a result of

the type of work they do.

The main risks posed are from unguarded machinery in the factory,

exposures to fertilizers, pesticides and other agro-chemicals, and,

accidents caused as a result of the terrain in the fields.

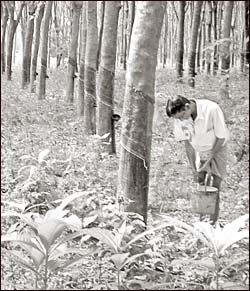

Most of the field workers are required to work on high altitudes and

uneven terrain under wet weather conditions.

Many chemical hazards exist in this sector. Although Sri Lanka does

not manufacture many chemicals, they are widely used in all economic

activities today. About 200 varieties of pesticides are formulated in

the country.

Large quantities of pesticides and fertilizers are used in the

agriculture sector, where 37 percent of the labour force are employed .

Occupational diseases resulting from exposure to chemicals are also

under-reported or not reported at all, possibly due to poor diagnosis.

From the large number of cases of acute pesticide poisoning it could

be presumed that many thousands of cases of chronic poisoning are not

even diagnosed. It appears to be obvious therefore, that there is a need

to take action in the field of chemical safety and prevention of major

occupational diseases and accidents at a national level.

The high number of cases of pesticide poisoning clearly indicates

that safety awareness in the use of chemicals is rather low.

Sri Lanka being a primarily agriculture-based society lacks the

necessary safety training and education.

According

to the Health Ministry’s statistics on pesticide poisoning, in 1993 the

number of reported deaths was 3477. According

to the Health Ministry’s statistics on pesticide poisoning, in 1993 the

number of reported deaths was 3477.

This figure had declined to 1677 in 1995, and down further to around

75 percent now, of which is a positive sign in the effort to increase

safety levels in the agricultural sector.

In the rubber sector large quantities of chemicals are used as

fertilizers and pesticides. Many accidents have taken place among the

users of these pesticides, who are mainly estate labourers and their

families.

Many different varieties of pesticides, herbicides and fertilizers

are used in the plantations every day. The quantities used vary from

estate to estate.

These pesticides and fungicides, most often, are not transported and

stored in a safe manner.

Unauthorized or poorly trained persons are sometimes involved in

preparation of pesticides. In the mixing of concentrate, safety

precautions are often neglected by these persons. Measuring utensils and

personal protective equipment are improperly used or not used at all,

thereby causing serious exposure hazards. There are instances where

entire communities have been affected due to fungicide sprays

contaminating waterways and wells. There have also been instances of

plantation workers being poisoned after consuming food in the fields

that were contaminated by chemicals.

Legislation

The Principal Legislation in Sri Lanka relating to safety of workers

is embodied in the Factories Ordinance Act No. 45 of 1942 and subsequent

amendments.

However, there are other pieces of Legislation that includes sections

on welfare of employees, sanitation, safety and accident prevention to a

certain extent.

The payment of compensation to injured workers is defined in the

Workmen’s Compensation Ordinance Act No 19 of 1934 and its subsequent

amendments.

Safety and health legislation was first introduced in Sri Lanka in

1896 with the enactment of the Mines and Machinery Protection Ordinance

No.2. After four decades, basic legislation covering safety, health and

welfare in factories was introduced in 1942.

The Factories Division of the Labour Department was set up in 1949

and the Factories Ordinance became operational in January 1950. However,

the Factories Ordinance does not cover safety of field workers, such as

farmers in the Agricultural Sector, in which 38.9 percent of the working

population of Sri Lanka are employed at present.

Only industrial hazards are covered by the Ordinance. The Factories

Inspectorate comprise a team of engineers, doctors and scientists

attached to the Labour Department who are in charge of enforcement of

the Factories Ordinance. In addition to the Factories Ordinance there is

the Shop and Office Employees Act, the Workmen’s Compensation Ordinance,

the Environment Act and the Control of Pesticide Act that cover safety

and health of workers in Sri Lanka to a certain extent.

The Environment Act and the Control of Pesticide Act mainly cover

safety in the use of chemicals, and, protection of users and the

environment from harmful effects of chemicals.

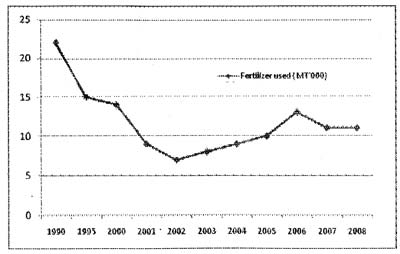

Use of fertilizer in rubber

Among the plantation crops, rubber recorded the lowest use of

fertilizer. In 1990, 22,200 metric tons of fertilizer was used in the

rubber sector. In 2000, the quantity used came down to 13,800 metric

tons, and subsequently it came down further to 10,500 metric tons in

2008.

The fluctuating prices for rubber, the unfavourable weather

conditions during the last few years and more importantly the global

financial crisis in 2008 may have contributed to the decreasing trend in

fertilizer application.

The absence of a fertilizer subsidy scheme may have also contributed

to the decreased use of fertilizer.

The graph indicates the amount of fertilizer utilized by the rubber

sector during the last decade. The usage of fertilizer has decreased

sharply after 2000.

Yet, the use of 10,500 metric tons in 2008, and the 30-35 percent

loss of nutrients due to leaching, fixation, erosion, surface run-off,

volatilization losses amounting to about 3,150 metric tons, is

considered substantial in terms of environmental pollution.

|

Field workers are required to work on high altitudes and uneven

terrain under wet weather conditions |

Application of herbicides

Herbicides are commonly used in rubber plantations to destroy weeds

and other unwanted plants that threaten the growth of the rubber plant.

Fairly large quantities are used daily in the fields as they are

known to destroy a variety of weeds and fungi that affect the rubber

plant.

These herbicides are found in powder and liquid form, and needs to be

diluted to the necessary levels before they could be used. Many workers

are unaware of the risks to health at the point of preparation.

Personal protective equipment is not used properly, therefore,

leading to contamination either by inhalation of chemical dusts or

dermal absorption of liquid formulas.

Application of pesticides

The safe use of pesticides is determined by the care and attention

given to precautionary measurers before, during and after application.

In the plantations the scale of operation, the area of application and

the form in which the pesticide is applied is important.

These pesticides are manufactured locally and are available in the

local market under different trade names.

In Sri Lanka, the control of Pesticides Act No.33 of 1980, provides

for the licensing of pesticides, the regulation of import, packing,

labelling, storage, formulation, transport, sale and use thereof.

This is the only law that deals with classification and labelling of

chemicals and applies only to pesticides. The labelling regulation

specifies the contents, languages and the size of the lettering, the

danger symbols and colour codes, precautions to be taken in handling,

first aid and antidote etc. However, most of the plantation workers are

illiterate, therefore, cannot comprehend some of these precautions. It

is vital that these employees are properly trained in the handling of

chemicals.

Factory wastes

The natural rubber (NR) collected as latex by tapping the bark of

rubber tree is one of the excellent raw materials suitable for many

industrial products.

The dry rubber content (DRC) of latex is about 30 percent and

non-rubber part is about 70 percent.

This 70 percent of non-rubber part together with water used for

processing is discharged as the wastewater from rubber factories

Large amount of this waste water discharged into the surrounding

environment by rubber factories creates a significant level of

environmental pollution and health hazards due to the presence of

non-rubber substances (organic matter ) and traces of various processing

chemicals. It is estimated that about 40-45 litres of rubber effluent is

generated by 1 kg of crepe rubber production.

It is rather discouraging to note that only few estate management

companies provide safety training for plantation workers. It appears

that only about 27 percent of the estates provide continuous safety

training on a structured basis, and, these were the estates on which

very few accidents took place or no work related accidents took place

during the period covered by this study.

The training is predominantly in the area of chemical safety, where

workers are trained in the safe use of pesticides, fungicides and

fertilizer is done by many estates. Some estates conduct few programs on

OSH.

Among the training programs conducted, the focus is mostly on the

safety in the use of tools and equipment, proper use of personal

protective equipment, safe formulation and use of pesticides and

weedicides and good house keeping practices.

Storage facilities

Planning and proper maintenance of storage areas is important in the

plantations as large quantities of fertilizer and pesticides are stored

within the estate. The hazards related to the fertilizers and pesticides

can be grouped into storage, transport and application.

Proper housekeeping is essential when working with dangerous

substances to avoid any unwanted chemical reactions.

Proper transport, loading and unloading procedures are also vital for

safety. It is encouraging to note that some estate managements have

taken adequate steps to provide proper storage facilities.

Employees involved

About 5,000 employees are directly engaged in tasks such as

preparation of fertilizer, pesticides, fungicides and spraying them in

the fields.

In some instances, the employees who were engaged in jobs such as

fertilizer mixing and pesticide spraying were rotated on the job from

time to time.

This is important as it is not advisable to engage an employee in

tasks such as pesticide spraying and fertilizer preparation for long

periods as the amount of exposure time to the chemical increases.

Most of the Superintendents have realized this fact, however, in some

cases the employees are engaged in these jobs on a full time basis..

Personal Protective Equipment (PPE)

Most agrochemicals used on the rubber plantations and the machinery

used in rubber production and working conditions present a risk to the

plantation worker. Engineering control measures could control some of

these risks.

However, the demographic conditions and the nature of work on the

rubber plantations make engineering control measures difficult.

PPE therefore, remains a necessary part of working with

agrochemicals. The protection required would depend on the degree of

hazard, the harmful effects of the agrochemical and the way in which it

is prepared and used. In the rubber plantations proper eye and face

protection, respiratory protection, protective gloves and working

clothes are important when pesticides and fungicides are formulated or

sprayed.

Way forward

The rubber sector unlike in other economic sectors, relatively

difficult working conditions, illiterate and sometimes ignorant workers

and hazardous work environments make occupational accidents and

illnesses very common among the plantation worker.

Workers have limited access to specialized advisory services and

often young persons are employed on the estates making them more

vulnerable to occupational hazards.

The majority of estates do not have safety committees or a full time

safety officer. In many cases personal protective equipment are not worn

by workers or not in proper working order.

Fire drills are not conducted in factories and workers are not

trained in fire fighting. Many employees are paid allowances for

accepting to do tasks, which involve physical risks.

These negative factors, in many instances, have been barriers to

implementing sound safety and health schemes.

It is also important to consider the differences among working people

in Sri Lanka, and the effects the type of work they do has on their

health.

The main concern is that some workers in particular types of industry

are more vulnerable than others. In the plantations, children help their

parents on the estates to raise income levels of the family.

Women form the major proportion of Sri Lanka’s plantation labour

force, and due regard should be paid to their dual role, family needs,

and difference in educational levels, physique and mental capacities.

The disabled and the older workers do not have the same mental and

physical capacity for work as their younger and healthier counterparts.

Their needs and capacities have to be taken into consideration when

providing work.

With the change in the demographic pattern in Sri Lanka a larger

proportion of aged workers are expected by the next decade, and this

will have to be considered in formulating safety and health programs in

Sri Lanka.

Therefore, it is necessary to integrate a clear occupational safety

and health policy in national development plans.

The national policy should include better structures for tripartite

co-operation among Government, Employers and Workers including a

national tripartite consultative mechanism.

There is also the need to review existing legislation relating to

health and safety of workers. Safety and Health legislation in Sri Lanka

was first enacted in 1942, and does not cover all types of workers in

all economic activities as specified by the International Convention on

Occupational Safety and Health of the ILO. The need for employers’

organizations and trade unions to be more committed and organized to

handle OSH issues should be emphasized.

The national policy and program on OSH should include workplace level

organization of health and safety activities involving both employers

and workers.

Although the employer is legally responsible for the safety and

health in the workplace, the joint participation of employers and

workers is necessary to deal with practical problems relating to

occupational hazards within the workplace in a flexible manner. |