Toyota way in a state owned hospital

Lal Fonseka Lal Fonseka

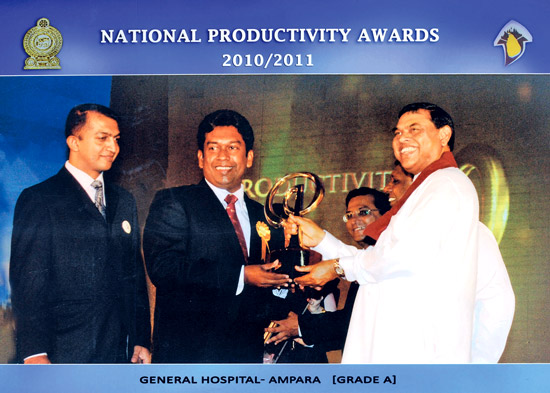

Very recently I conducted a successful surveillance audit of ISO

9001:2008 in the Ampara General Hospital and within a space of another

couple of months, this Hospital has emerged as the overall winner in the

recently concluded National Productivity Award Competition. These two

significant feats of the hospital prompted me to write this article.

According to the information available with them, this is not the

first occasion where they have won an award of this calibre. Previously

in many instances, this particular hospital has been able to achieve a

number of awards locally and internationally. The details of those

awards are listed below. There are altogether 12 awards. Ampara General

Hospital is a state owned hospital and it is the only government

hospital which has been certified for ISO 9001:2008 for its Quality

Management System.

* 5 'S' Taiki Akimoto Merit award 2003

|

Overall Winner of the National Productivity Awards |

* Thaiki Akimoto 5 'S' Award - Winner (Service sector) First runner

up (For all aver the competition) 2004

* Tahiki Akimoto 5 'S' Award 1st runner all over the competition 2004

* National productivity awards service sector 3rd place 2004

* Nagaki Yamamoto special KAIZEN award 2005

* Provincial productivity award winner 2005

* National productivity award winner (Service sector Large Scale)

2005

* National Quality award winner service sector 2006

* National productivity Gold award winner (Service & Manufacturing

service sector) 2006

* International Asia Pacific quality award (Health Care) 2007

* National Productivity Award 2010/2011- Grade A

* National Green Award 2012- Silver

Undoubtedly this is a rare feat achieved by a government hospital and

it is the outcome of the fantastic team-work this hospital has in their

day to day work performance.

What is a hospital?

A hospital is an institution for health care providing patient

treatment by specialized staff and equipment, and often but not always

providing for longer-term patient stays. A hospital today is a centre

for professional health care provided by physicians and nurses. The name

comes from Latin hospes (host), which is also the root for the words

hotel and hospitality.

As usual in any other organisations, even in hospitals unless they

delight their customers who happened to be the patients (In-door or

Out-door), clients of such hospitals will look out for alternative

service providers. At the Ampara Hospital, since they always take every

possible attempt to make their patients delight and happy, it has become

a very popular hospital in the country. As per the hospital

administration, almost every week they have got to entertain outside

parties and organisations who come to see their achievements. Under

these circumstances, winning quality awards of this nature cannot be

treated as a miracle.

As per the well written management protocol of Ampara General

Hospital, when a new patient arrives at the hospital, the triage nursing

Officer will refer the patient either to the Out Patients Department (OPD)

or the Primary Care Unit (PCU) on the condition of the patient. All

admission to the hospital from 8pm to 7am will be done through PCU and

7am to 8pm admissions will only be done through OPD or triage referrals.

All Critically ill patients are admitted through the PCU and on the

findings of this unit; decisions are taken whether to give treatments

in-ward or out-door to the patients. Ampara is a general hospital, which

is set up to deal with any types of diseases and injuries, and typically

has an emergency ward (PCU) to deal with immediate threats to health and

the capacity to dispatch emergency medical services. A general hospital

is typically the major health care facility in its region, with large

numbers of beds for intensive care and long-term care, facilities for

surgery and childbirth, bio assay laboratories, and so forth. Larger

cities may have many different hospitals of varying sizes and

facilities. But this is a wonderful hospital and it is worthwhile making

a special trip to Ampara to see its ambiance and the quality service.

For decades, it has been a common belief that success in the

marketplace was dependent upon organisations' ability to create

satisfied customers. This was revealed in researches done by (Arnold et

al., 2005; Parasuraman et al., 1985; Reichheld and Sasser, 1990; Rust

and Zahorik, 1992, 1993). In fact, early scholars argued that the

creation of a satisfied customer was the fundamental core of businesses

or service centres (Drucker, 1973). Consistent with this argument is the

fact that one of the central themes of the marketing concept is

delivering products and services that satisfy customer needs. In return,

satisfied customers are expected to exhibit behaviours that are

favourable to the organisations, such as future patronage and making

recommendations to others.

Because of the recognized importance of customer satisfaction, it has

been a topic that has generated substantial attention among

academicians.

Emphasis on customer satisfaction often stems from the thought that

keeping current customers is much less expensive than attempting to

attract new customers. Similarly in a hospital customers are the

patients.

But another significant point that was noticed in Ampara Hospital is

that they do not call these customers as patients. Instead, they call

them as clients.

They are the people who come to the hospital seeking some redress or

relief.

During my audit as was mentioned at the very beginning of this

article, it was also observed that Ampara has adopted the world famous

Toyota Production System successfully in carrying out their day to day

functions. According to my knowledge, it is the only hospital in Sri

Lanka which has adopted the Toyota Production System in a highly

effective manner.

The Toyota Way is a set of principles and behaviors that underlie the

Toyota Motor Corporation's managerial approach and production system.

Toyota first summed up its philosophy, values and manufacturing ideals

in 2001, calling it "The Toyota Way 2001." It consists of principles in

two key areas: continuous improvement, and respect for people. As was

told before, Ampara Hospital successfully applied the Toyota way in its

hospital. The number of awards won by the hospital will be

self-explanatory for implementation of Toyota way in the hospital.

The two focal points of the Toyota principles are continuous

improvement and respect for people. The principles for a continuous

improvement include establishing a long-term vision, working on

challenges, continual innovation, and going to the source of the issue

or problem. The principles relating to respect for people include ways

of building respect and teamwork.

Research findings

In 2004, Dr. Jeffrey Liker, a professor of industrial engineering,

published "The Toyota Way." In his book Liker calls the Toyota Way, "a

system designed to provide the tools for people to continually improve

their work." The system can be summarized in 14 principles.

According to Liker, the 14 principles of The Toyota Way are organized

in four sections: (1) long-term philosophy, (2) the right process will

produce the right results, (3) add value to the organization by

developing your people, and (4) continuously solving root problems

drives organizational learning.

Long-term philosophy

The first principle involves managing with a long-view rather than

for short-term gain. It reflects a belief that people need purpose to

find motivation and establish goals. In this aspect, Ampara Hospital

administration has managed the hospital with a long-view especially on

the followings.

1. The external environment: This includes such factors as

performance monitoring and management; and the availability of

cost-effective treatments and technologies including the beautiful

surroundings.

2. Hospital management: This covers such factors as leadership and

the use of effective management practices; cooperation between director

and clinicians; and the speed at which new and cost-effective treatments

and technologies are adopted

3. Hospital operational processes: These include the control of

labour costs; the use of Nursing skill-mix by giving them adequate

training; shortening length of stay in the hospital by patients; and

measures intended to reduce errors and increase quality.

Right process will produce right results

The next seven principles are focused on process with an eye towards

quality outcome. Following these principles, work processes are

redesigned to eliminate waste (Muda- Japanese word for waste) through

the process of continuous improvement - Kaizen. The seven types of muda

are (1) overproduction/service; (2) waiting, time on hand; (3)

unnecessary transport or conveyance; (4) over processing or incorrect

processing; (5) excess inventory; (6) motion; and (7) defects.

The principles in this section empower employees in spite of the

bureaucratic processes of State Sector, as any employee in the hospital

system to take corrective and preventive action to extend an effective

quality service emphasizing that quality takes precedence which is known

as Jidoka in the Toyota Production system. Jidoka means in brief is

automation with human touch. In another way we could describe it as

autonomation which prevents the defective services, eliminates

overprovision of services and focuses attention on understanding the

problem and ensuring that it never recurs. It is a quality control

process that applies the following four principles.

1. Detect the abnormality.

2. Stop doing excessive work

3. Fix or correct the immediate condition.

4. Investigate the root cause and install a countermeasure.

The way the Toyota bureaucratic system is implemented to allow for

continuous improvement (kaizen) from the people affected by that system

so that any employee may aid in the growth and improvement of the

company.

Recognition of the value of employees is also part of the principle

of measured production rate which is termed as Heijunka. On a production

line, as in any process, fluctuations in performance increase waste.

This is because equipment, workers, inventory and all other elements

required for production must always be prepared for peak production.

This is a cost of flexibility. Even in Ampara Hospital, fluctuations in

performance is controlled through implementing decease preventive

programs such as Combatting Malaria, Dengue and also having an isolated

ward for infectious deceases such as TB and Chicken Fox etc.; this is

known as demand amplification

These principles are also designed to ensure that only essential

materials are employed (to avoid over services), that the work

environment is maintained efficiently (5SProgram) to help people share

work stations and to reduce time looking for needed tools, and that the

technology used is reliable and thoroughly tested.

Value to organization

Human development is the focus of principles 9 through 11 in Toyota

Way. Principle 9 emphasizes the need to ensure that leaders embrace and

promote the corporate philosophy. This reflects, according to Liker, a

belief that the principles have to be ingrained in employees to survive.

Same thing applies in Ampara Hospital which is the very reason employees

including the clinicians attached to the hospital wish to stay back in

the hospital for longer periods. The present director has been working

in the same hospital for last 10 years while the senior matron's service

is more than 10 years.

I am told that even certain consultants do think twice before

accepting the transfer orders. The 10th principle of Toyota way

emphasizes the need of individuals and work teams to embrace the

company's philosophy, with teams of 4-5 people who are judged in success

by their team achievements, rather than their individual efforts.

In the Hospital, team-work is eminent very clearly through which

hospital's philosophy is embraced by the various teams and departments

of the hospital. Principle 11 looks to business partners, who are

treated by Toyota much like they treat their employees. Toyota

challenges them to do better and helps them to achieve it, providing

cross functional teams to help suppliers discover and fix problems so

that they can become a stronger, better supplier. This is another area

Ampara Hospital is heavily concentrating and they too always try their

level best to achieve the expectations of Ministry of Health and the

Society and also to treat their suppliers to their maximum satisfaction.

Solving root problems drives organisational learning

The final principles embrace a philosophy of problem solving that

emphasizes through understanding, consensus based solutions swiftly

implemented and continual reflection and improvement. Consensus

decision-making is a group decision making process that seeks the

consent of all participants. Consensus may be defined professionally as

an acceptable resolution, one that can be supported, even if not the

"favorite" of each individual. Here again in this hospital, Cross

Functional Teams' meetings are frequently held and the Internal Quality

Audits are being conducted at least once in every 6 months. Management

Review Meetings are also held once in every six months and consensus

based decisions are taken and implemented. This is a highly effective

tool which the hospital does always use for their continual improvement.

The 12th principle sets out the expectation that managers will

personally evaluate operations so that they have a firsthand

understanding of situations and problems. This is sometimes referred to

as "Get your boots on" and go out and see what is happening due to its

similar cadence and meaning. It has also been compared to Peters and

Waterman's idea of "Management by Wandering Around". This concept

quickly became so universal that new managers instinctively knew that

they had to "walk around" in order to achieve high effectiveness levels.

Whilst these ideas, with their associated lists of how-tos, are probably

good ideas they may miss the essential nature of Genchi Genbutsu which

is less to 'visit' and more to 'know' by being there. Toyota has high

levels of management presence on the production line whose role is to

'know' and to constantly improve. Similarly even in Ampara Hospital, all

heads of the departments including the Director have a habit of making

frequent visits in the entire hospital just to see what happens in the

key areas such as Clinical Wards and Surgical Theaters. During these

visits, actions where it is necessary are taken on the spot.

Principle 13 like in the Toyota Production System encourages thorough

consideration of possible solutions through a consensus process, with

rapid implementation of decisions once reached at Ampara Hospital. This

is known as Nemawashi in Japanese Language. It means an informal process

of quietly laying the foundation for some proposed change or project, by

talking to the people concerned, gathering support and feedback, and so

forth. It is considered an important element in any major change, before

any formal steps are taken, and successful nemawashi enables changes to

be carried out with the consent of all sides.

The final principle requires that Toyota be a "learning

organization", continually reflecting on its practices and striving for

improvement. According to Liker, the process of becoming a learning

organization involves criticizing every aspect of what one does. There

is no doubt about this principle as far as the Ampara Hospital is

concerned as it is a learning organization. By looking at the awards

they have won since year 2003 onwards, how can anyone say anything

against it?

However, one of the strongest findings observed in Ampara Hospital

was that good leadership, and effective general and clinical management

which are both crucial for making productivity gains. I do now believe

that after reading this article, you are now tempted to make a visit to

the hospital as to see how they have successfully adopted the Toyota way

in their operations. |