Supply chain and the rules of the game

Peter Barbut CMILT Country Representative Supply

Chain Asia - Forum

This article is a continuation of the writer’s intention to make

public awareness of the ‘supply chain’ process and for the benefit of

students who would like to take-up career’s in this field which is today

developing a good demand in the manufacturing sectors due to

‘globalization’.

Supply

chain management is a difficult game to master. It requires you to move

a great many pieces in a very specific ways, and you have to choreograph

those moves to make each piece arrive in the right place at the right

time. Supply

chain management is a difficult game to master. It requires you to move

a great many pieces in a very specific ways, and you have to choreograph

those moves to make each piece arrive in the right place at the right

time.

It’s also a game that plays out on grand scale, with a playing field

that spans the entire planet. Fortunately, the rules of the game - the

descriptions of the pieces and the ways they move - are simple enough to

be summarized in a few pages.

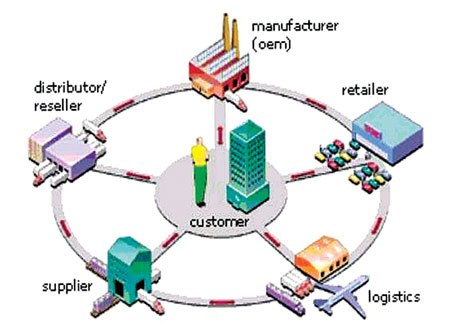

In a nutshell, supply chains consists of production and storage

facilities connected by transportation lanes, and they exist to support

the flow of demand, supply and cash.

The difficulty of managing supply chain comes primarily from the

complexity that creeps into their structure and the variability that

characterizes their flows.

It’s this complexity and variability that makes an easy game hard to

master.

Facilities and links

A supply chain is a network of facilities, connected by

transportation lanes, Facilities, Production facilities, storage

facilities. Transport lanes are mode of transportation; they include

roadways, railways, waterways, sea lanes, air lanes, and pipelines.

Viewed in the largest context, supply chains consumers of the finished

good, the people who actually put those goods to their intended purpose.

Facilities contain controlled quantities of materials called

inventories. Production facilities hold inventory in three different

forms: Raw materials inventory consist of materials ready for

utilization in the production: work-in-process (WIP), inventory includes

all materials currently being worked on: and finished goods inventory

holds completed products ready for shipment.

Storage facilities vary: Warehouses usually contain only a single

kind of inventory, but distribution centers that do the final assembly

all three kinds.

Cross docks, which are used only to transfer goods between trucks, do

not contain any in separately managed inventory. Retail stores also vary

in, this regard.

Custom bicycle shops have all three types if inventory

warehouse-style stores contain only one and some appliance stores carry

none at all.

Lanes are used by vehicles and containers

Lanes are used to move inventory between facilities along a

particular mode of transportation, using a combination of vehicles and

containers.

Some vehicles, such as a truck and railway engines, can be decoupled

from their containers, whereas other such as delivery vans and tanker

ships, have container holds the cargo built in.

Decoupling is an important consideration because it offers more

flexibility in routing, dispatching, temporary storage, and other

transportation activities. In case of pipelines, the functions of the

vehicle and the container are merged with the lane itself, with pumps

providing the motive force and pipes containing the inventory in

transit.

Transport modes offer trade-offs

Each mode of transportation offers a unique mix of speed, cost,

availability, and capability. For example, shipping by air is fast,

expensive, available from all large cities, and limited to small and

lightweight packages.

By contrast, shipping by sea is slow, cheap and availability only to

cities with ports, and virtually unlimited with regard to size and

weight.

There are also different volume trade-offs within each mode. In

trucking it is much cheaper to send full truckload (FTL) shipments than

to use less-than truckload (LTL) shipments, and the FTL option offers

tighter control over the routing and timing of the shipment.

However, using FTL shipments requires building up more finished goods

inventory and may cause delays in shipments. Similar trade-offs apply in

the other modes.

Shipments can use multiple modes

Shipping within a limited geographical region normally uses a single

mode from source to destination. For larger distances, including most

international trade, shipments generally use two or more modes, a

practice known as Intern-modal transportation.

For example, a shipment might travel by rail to the nearest seaport,

cross the ocean by ship, and travel rest of the way by truck.

Inter-modal shipments are usually enclosed in steel containers that can

be transferred between specially fitted rail cars, container ships, and

tractor trailers.

Like facilities, transportation lanes contains inventory. This

in-transit inventory bridges the gap between the shipping facility’s

finished goods inventory and receiving facility’s raw material

inventory. In-transit inventory is different from other forms, in that

it is unavailable for use. Is at high risk of loss from theft and

accidents, and is subject to delays due to vehicle breakdown and lane

congestion. Along with raw materials, work in progress, and finished

goods, In-transit inventory represents the fourth major type of

inventory.

The distinction between in-transit inventory and the two inventories

it connects is often blurred in practice. Trailers or railcars are

frequently used to store finished goods at production facilities until

full loads are produced, In which case the goods are still part of the

plant’s finished goods inventory.

But if the storage is brief and the destination of the goods is

determined by the choice of containers, the goods in the container may

be treated as inventor in transit as soon as they are loaded.

Similar issues come up at the destination. Where full containers may

sit for days or weeks in a yard before being unloaded. In one rather

perverse practice, railway care are actually kept on the move, circling

in wide arcs around the facility, until there is space to park them in

the yard.

This is a very expensive way to hold inventory.

Package carriers are viewed as a mode

Although they don’t make use of a separate transportation medium,

package carriers such as UPS and FedEx are commonly viewed as a distinct

mode when making transportation decisions. In reality, these carriers

use a mix of air and highway transport to deliver their packages, using

their own fleets of aircraft and trucks.

As a practical matter, however, it doesn’t matter how a package is

conveyed because that decision is out of the shipper’s hands, so using a

packages carrier is viewed as an alternative on a par with shipping by

air, land or water. The trade-offs discussed for the other modes also

apply to package carriers.

They are fast, relatively expensive, available in most locations, and

limited to relatively small, lightweight products.

Demand, supply, and cash

The essential goal in managing a supply chain is to achieve an

orderly flow of goods from extractors to consumers.

It should not be surprising, then, that the deepest roots of the

discipline can be found in transportation management, which is

responsible for moving finished goods to the next link in the chain.

Over time, transportation management merged with a related function,

materials management, to form the broader discipline of logistics, which

handles the flow of materials all the way from suppliers through the

three internal inventories already explained in this article to the end

customer. |