How to breathe on the Moon

Katharine Sanderson

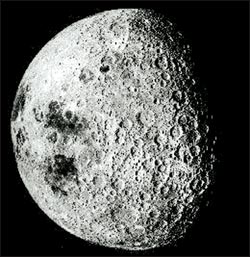

Scientists in Cambridge, UK, have developed a reactor that can make

oxygen from Moon rock, a vital technology if plans to create a lunar

base are to take off.

Whether tapping the Moon’s resources or using the satellite as a

jump-off point to explore the deeper reaches of space, occupants of any

future lunar base will need oxygen to survive. Ferrying huge amounts of

it to the Moon would be extremely expensive, perhaps costing as much as

US$100 million per tonne according to some estimates, so researchers are

examining potentially cheaper ways to produce oxygen on the Moon itself.

|

Moon rocks could be a source of oxygen for a future lunar base |

NASA has been looking for ways to get oxygen from Moon rock for

several years. In 2005, as part of its Centennial Challenges program,

the agency offered a US$250,000 prize to the first team to come up with

a piece of kit that could extract five kilograms of oxygen in eight

hours from some simulated Moon rock. Despite raising the value of the

prize pot to $1 million in 2008 with the help of the California Space

Authority, the prize remains unclaimed.

In addition, the agency’s ongoing In Situ Resource Utilization

program is currently looking at several different technologies for

extracting oxygen from Moon rock.

Now, Derek Fray, a materials chemist from the University of

Cambridge, UK, and his colleagues have come up with a potential solution

by modifying an electrochemical process they invented in 2000 to get

metals and alloys from metal oxides.

The process uses the oxides, also found in Moon rocks, as a cathode,

together with an anode made of carbon. To get the current flowing

through the system, the electrodes sit in an electrolyte solution of

molten calcium chloride (CaCl2), a common salt with a melting point of

almost 800 °C.

Eroding anode

The current strips the metal oxide pellets of oxygen atoms, which are

ionized and dissolve in the molten salt. The negatively charged oxygen

ions move through the molten salt to the anode where they give up their

extra electrons and react with the carbon to produce carbon dioxide, a

process that erodes the anode. Meanwhile, pure metal is formed over at

the cathode.

To make the system produce oxygen and not carbon dioxide, Fray had to

make an un-reactive anode. This was crucial: “Without those anodes, it

doesn’t work”, says Fray.

He discovered that calcium titanate, which is a poor electrical

conductor on its own, became a much better conductor when he added some

calcium ruthenate to it.

|

Flying oxygen to the Moon is likely to be expensive. |

This mixture produced an anode that barely erodes at all, after

running the reactor for 150 hours, Fray calculated that the anode would

wear away by roughly three centimetres a year.

In their tests, Fray and his colleagues used a simulated lunar rock

called JSC-1, developed by NASA. Fray anticipates that three reactors,

each a metre high, would be enough to generate a tonne of oxygen per

year on the Moon.

Three tonnes of rock are needed to produce each tonne of oxygen, and

in tests the team saw almost 100 percent recovery of oxygen, he says.

Fray presented the results last week at the Congress of the

International Union of Pure and Applied Chemistry in Glasgow, UK.

To heat the reactor on the Moon would need just a small amount of

power, Fray notes, and the reactor itself can be thermally insulated to

lock heat in. “It won’t be a problem”, he says.

Robust prototype

The three reactors would need about 4.5 kilowatts of power, not much

more than that used to heat an immersion heater in a domestic boiler,

which could be supplied by solar panels or even a small nuclear reactor

placed on the Moon.

With an extra £10 million (US$16.5 million), Fray says he would be

able to develop ‘a robust prototype’ of a bigger reactor that could be

operated remotely.

He is currently working with the European Space Agency towards this

goal.

A similar technique for oxygen extraction is being developed by

Donald Sadoway at the Massachusetts Institute of Technology in

Cambridge, Massachusetts, but his process works at a much higher

temperature of up to 1600 °C, which means that the Moon rock is molten

and can act as the electrolyte itself.

Molten metal

It produces molten metal, including iron, which sinks to the bottom.

Fray says that his process is more efficient because it works at a

lower temperature, but Sadoway insists that molten salt electrolysis, as

his technique is called, makes up elsewhere for the extra heat it needs.

“In Derek’s process, the molten salt allows him to operate at a much

lower temperature”, says Sadoway, but he still has to consolidate the

Moon rock into a solid form. This is often difficult because of the fine

sandy nature of Moon rock, he says.

Sadoway’s reactor could even build itself. The interior would be Moon

regolith, the powdery rubble that forms the Moon’s surface, heated

electrically to become molten, and the exterior would be solid regolith

that has cooled. “We form the wall of the reactor by allowing the molten

regolith to freeze”, he says, but admits that starting the process is

‘tricky’.

Sadoway says that with sufficient funding, he could have his system

scaled up within two years. His process has been short-listed by NASA

and is receiving some funding from the agency. “Once we solve the

materials problems at the lab scale we should be able to move quickly”,

he says.

Courtesy Nature News |