Under-exploiting environmental friendliness of rubber plantations

N. Yogaratnam ( PhD, London)

Chairman/ Tree crops Agro Consultants

|

Picture by Saliya Rupasinghe

|

Rubber (Hevea brasiliensis) has retained many features from it's

Amazonion origins as an environmentally friendly forest tree, although

it has been cultivated as a plantation crop for latex with wood as a

side-product and now for carbon credits.

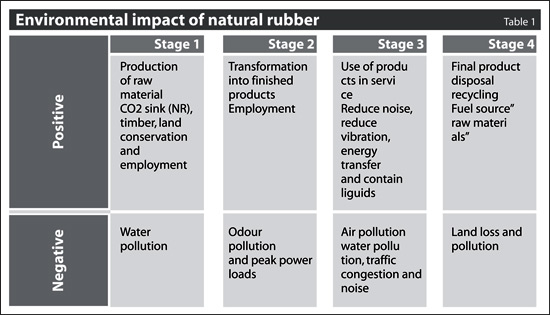

One key factor in the relationship between any activity and the

environment is that it is impossible to consider any individual activity

without reference to the overall impact. In the case of the rubber

industry, it is helpful to break down the activities which impinge upon

the environment ( Table 1) into those associated with (1) the production

of the raw material, (2) the transformation of the raw material into

finished products (3) the use of such products in service and (4) the

final recycling or disposal of the products.

Many studies relating to the last-named, such as investigations of

the scrap tyre problem, fail to recognise the importance of the other

elements which may either amplify or mitigate the problem.

It is unavoidable that many authors tend to base their analysis upon

natural rubber, frequently in comparison with synthetic rubber, but many

of the factors (such as factory emissions, product service and ultimate

disposal) apply to all elastomers.

In most discussions on the environment resources are divided into

renewable and nonrenewable categories. The former includes most natural

products. The latter includes most mineral resources, although many of

these are recyclable, and fossil fuels.

The Scandinavians tend to consider their large hydroelectric capacity

as a green resource. Fossil fuels are not only non-renewable, but their

combustion contributes to increases in global carbondioxide levels and a

possible green house effect which may even lead to higher ocean levels

and the loss of global land mass.

Industrial material

Natural rubber is an unusual industrial material as it is renewable

resource. As such natural rubber enjoys very considerable environmental

benefits, and these have tended to be understated in most discussions.

In broad energy input terms, natural rubber enjoys a very considerable

advantage over synthetic elastomers, whose energy inputs is in the

region of 210 - 275 GJ / tonne, as against 30 - 35 GJ / tonne in NR

production.

It is probable that the synthetic rubber industry has now reduced its

energy inputs for processing and that the use of yield stimulation etc

may marginally increase the energy consumed in natural rubber production

besides increased fuel costs. It is probable that the synthetic rubber industry has now reduced its

energy inputs for processing and that the use of yield stimulation etc

may marginally increase the energy consumed in natural rubber production

besides increased fuel costs.

Nevertheless, the natural rubber production data assumes

long-distance transportation for the raw rubber from the producing

countries to the major consumers.

Rubber wood

Since there has been a significant shift in rubber product

manufacturing to the natural rubber producing countries and this will

have marginally reduced energy inputs, although these will have been

balanced (except in the case of latex goods) by increased energy costs

for the transport of manufactured goods.

In the case of latex goods, the non-transport of water around the

world must represent a very considerable environmental gain.

The use of rubber wood is growing rapidly and Hevea is even being

grown primarily as a source of timber, with rubber being produced as a

by-product. Rubber wood is used in furniture, flooring , building

components, chipboard, etc and enjoys a growing market. Obviously, the

timber so-produced is an eco-friendly material and it is highly

pertinent to note that some of the companies involved are subjecting

rubber wood production to environmental audits.

It has been estimated that the energy input for wood as a raw

material is about 6 GJ / tonne as compared with 38 GJ / tonne for steel

and around 100 GJ / tonne for most thermoplastics.

CO2 sequestration

The most understated aspect of rubber cultivation is that of a sink

for the carbondioxide which is produced by animals (including man), the

natural combustion of plant tissue, and especially through the burning

of fossil fuels. Photosynthesis enables the carbondioxide to be

converted into life-sustaining oxygen whilst fixing the carbon as

biomass.

Hevea's effectiveness in this respect is probably at least equal to

that of virgin forest and may even exceed it.

Tropical forests, which cover 20 percent of the earth's surface,

account for at least 25 percent of global terrestrial carbon fixation,

and it is becoming increasingly recognised that the forest makes a major

contribution to global ecology. Hevea rubber compares well with virgin

jungle in terms of biomass, especially once the trees reach maturity.

Physiological studies have shown that Hevea is more effective than teak

grown in plantation conditions in taking up carbondioxide.

This is probably due to the extra energy required to produce the

latex inside the tree: thus, in contrast to a synthetic rubber plant,

which consumes energy and produces carbondioxide to convert pure energy

( crude oil) into elastomers, the natural rubber plant converts carbon

dioxide into an elastomer.

The biomass production potential of a plant species is related to its

photosynthetic capacity per unit leaf area and the total leaf area

produce per plant. In full sunlight the photosynthetic rate of a mature

rubber leaf is around 11 æmol/m2/s1 as compared with 5 - 13 æmol/m2/s1

in other tree species. The leaf area produced by a mature rubber tree is

quite substantial : the leaf area index of a mature rubber plantation

can be as high as 6 or 7. Because of the high photosynthetic rate and

leaf area index, the biomass production per unit land area within a

given time is very high in Hevea. With a planting density of 500 trees

per hectare the canopy closes in less than five years.

Agronomic efficiency

Natural rubber does not impoverish the land upon which it is grown.

Fertiliser inputs are very low and the surrounding soil appears to be

enriched by the abundant leaf fall.

Furthermore, biodiversity remains remarkably high in rubber

plantations in marked contrast to most forms of monoculture. Excellent

agronomic techniques assist in the conservation of the environment

within rubber plantations.

Measures include terracing, slit pitting, bunding and mulching and

the growth of leguminous cover plants between the rows to assist with

nitrogen fixation. Biomass burning is now discouraged during replanting.

Moreover, it is possible to grow a wide variety of crops during the

tree's immature period, further enhancing its environmental credentials.

Energy inputs

It is possible to produce dry rubber with remarkably low energy

inputs especially if maximum use is made of human and solar energy. It

is possible to produce air-dried sheet solely by the exploitation of

these two forms of energy. Most dry rubber and latex concentrate

production does exploit modest inputs of electricity ( which in many

producing countries is green power from hydro generators) and other

forms for drying. Obviously energy is also required to convert dry

rubber into a form where it can be shaped and vulcanised.

Unfortunately, primary processing of natural rubber can lead to

significant environmental pollution, especially of water courses and

through localized unpleasant odours. Considerable progress has been made

in reducing water-borne pollution. especially in India, Malaysia and Sri

Lanka. But, in most countries, a considerable problem still remains.

This endangers many other activities such as the use of water for

agriculture for industrial use and for fish cultivation.

In-service segment

There are both positive and negative environmental factors in the

in-service segment of an elastometric product life cycle. The positive

factors include a reduction in environmental noise., although tyre noise

is a major contributor to environmental disturbance from roads,

especially where vehicles travel at high speed. A clear positive

contribution to noise and vibration control is to be found in the

application of elastometric mountings and bearings.

The negative factor, for it is essentially one, is that the main

outlet of rubber is in association with the automotive industry. The

road transport industry accounts for disproportionate uptake of the

world's natural resources. In the USA, it has been reported that

approximately 25 per cent of crude oil is consumed in personal

transportation.

This industry is a major contributor to global increases in

carbondioxide emissions and endangers health, especially that of

children, through asthma and other dangers. It must be stressed that

these effects are not directly associated with the use of rubber, but

that the system which induces them is inherently dependent upon rubber

for its tyres, its engine mounts, its weatherstrip and so on.

In the product lifecycle, it is seen that the energy required to

manufacture or dispose of a passenger car tyre is trivial in proportion

to that associated with its use in service.

The need for physical travel will be reduced by the general

availability of modern methods of telecommunication and increases in

computing power. As is so often the case with global problems, solutions

are found just when the problem appears to be becoming insurmountable.

Working at home is increasing and this will go some way towards

resolving the problem for some people of commuting by road. People may

learn to make less use of their personal vehicles and make greater use

of public transport.

The United Kingdom's Royal Commission towards public transport

considered the human attitudes will have to be changed towards public

transport.

Obviously, if this happens there will be a decrease in the demand for

elastomers especially in the traditional western markets, but this will

be offset by uptake in the developing nations which really need road

vehicles to survive - to avoid localised famine and disease and to

provide relief from natural disasters.

Product life extension

Product life extension is an important contributor to lessening the

environmental impact of any activity. This can either be achieved by

extending the life of individual components, or through prolonging the

life of the system in which they are situated, or both. In some cases it

may be possible to prolong product life through reconstruction once or

more during the lifecycle.

An excellent example of this was the multiple retreading of aircraft

tyres. The automotive industry demands that products should , as far as

possible, last for the entire life of the vehicle and this has greatly

affected the character of many elastrometric components.

At one time, cautious motorists used to carry spare fan belts and

even radiator hose as it was anticipated that there was a reasonable

probability of failure. Such caution is no longer required. Hose and

belts last the life of a vehicle unless some catastrophe occurs. Wiper

blades and tyres are still changed, but at decreasing intervals.

It has been predicted some time ago that car tyres will last for the

life of the vehicle within the period 2010 - 2020 and that truck tyres

will have 2,400,000 km casings. These forecasts are probably to be no

more than wishful thinking. Nevertheless, some progress is being made

towards increasing tyre life.

Careful design of tyres can save weight and reduce fuel consumption

and thus produce marginal improvements in what is an extremely wasteful

system. Similar enhancements could be achieved by reduced speed limits.

Such measures would also reduce pollution and would marginally increase

road capacity. Reduced speed limits would also encourage the use of

other less wasteful transport modes such as train services.

Retreding

An increase in retreading activity is probably the greatest

contribution made by the tyre industry. There had been far greater

retreading activity in truck tyres, than in passenger tyres, and as

noted aircraft tyres were routinely retreaded many times. The lack of a

vigorous retreading industry for passenger tyres stems from (1) the

great variety of sized and styles of original equipment, (2) the

relatively low carcass strength ( which partially reflects the quest for

lower weight to reduce fuel consumption), and (3) the dangerous tendency

for car drivers to use tyres to beyond the point at which they are

retread able - and safe. There is also a lack of the strong

infrastructure which enables companies to have their tyres serviced on a

routine basis : this infrastructure enables retreading to be performed

as part of a tyre supply operation. Clearly, it is impossible to

envisage such an operation for private cars, unless Government

regulation and standardization are imposed. Such an imposition would

have the benefit of discouraging motorists to drive with tyres which are

no longer fit for service.

Recycling

A few elastomeric products are disposable, especially those

manufactured from latex ( gloves and balloons, for instance). In the

case of balloons these will naturally degrade within about a month if

left upon the ground. Unfortunately, medical gloves have to be burned

alongside other disposable medical items to eliminate the pathogens

which may be present.

Elastomers are difficult to recycle. The problem can be eased through

the use of thermoplastic elastomers, although damage in service (

especially through exposure to fuels and the combustion products from

fuels) may lessen the value of such materials to a point below which it

is valid to expend the effort required for recycling. It is possible to

reclaim rubber but this industry is only exploited on a large scale in

India where there is a plentiful supply of labour and the demand for

elastomeric raw materials greatly exceeds the supply.

It must be remembered that the carbondioxide produced is not a

problem for the natural rubber element of the tyres as this will be

recycled by the rubber trees that produced it in the same way that it is

possible to grow biomass as source of fuel Pyrolysis is interesting as

there is no air pollution problem and the products other than heat, are

in the form of gases ( which can be burned), solids include a form of

carbon black, which if the input consists predominantly of natural

rubber, can be clamed to be 'green".

There is a growing recognition that the global ecosystem cannot

continue to tolerate the present wasteful use of materials. The rubber

industry is fortunate in that over one third of its key raw material is

based upon a self-sustaining resource which is not only capable of

reabsorbing the carbon dioxide generated from its disposal and through

it use, but also provides timber as valuable, environmentally-friendly

by-product. The natural rubber industry is based upon minimal

environmental disturbance, and is far less than that required to produce

typical food crops. Nevertheless, it cannot be forgotten that the

primary end use is in personal transportation, much of which is

extremely wasteful in terms of resources.

E-mail: [email protected] |